Uncertainty, volatility, and erratic demand has affected business performance, while disruptions to supply chains and ways of working have required rapid change and often significant crisis management, with limited resources. As we look to the future, this uncertainty is set to continue with no clear end in sight. Every week brings new changes, new predictions about impact, and new economic shocks. And this is not just limited to the virus, as Brexit, global political uncertainty, and the long-term impact of the economic cost on government finances all raise major concerns.

The emotional impact on leaders cannot be underestimated. However, the danger is that given all the uncertainty and impact, the opportunity to prepare for a successful recovery might be missed. All indications point towards new opportunities for rapid growth and market and product innovation once the impact of the pandemic subsides. Through re-alignment, re-invention, and catering for the change in consumer mindsets, the best companies will come out leaner but stronger.

Returning your business to its pre-Covid state might seem like a comfortable first step during these times, but it will also be an opportunity missed. What is required is to go “back to the future” and make decisions that position you for greater success and sustainability.

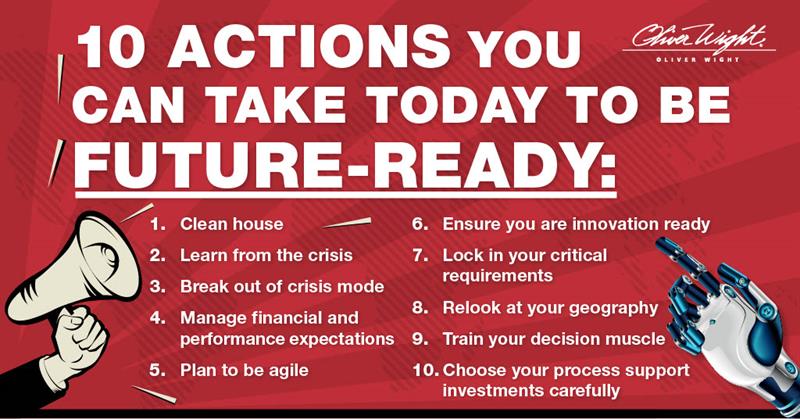

Getting ready for the future is not only about a brand-new strategy or a total change in business model. It is about preparation, alignment and prioritisation. It is about laying the groundwork now for a period of sustained but uncertain growth. It is about freeing up the focus and energy that is consumed by the crisis of the moment. And it is about making the right decisions when faced with difficult choices in a world of limited investment in equipment and people.

One of the clients we are supporting during the pandemic has made specific provision in their diaries and meetings for recovery planning. Leaders are consistently challenged to present their plans for scenarios where there was a rapid growth curve, from portfolio to capacity to supply risk, and cannot use a lack of time as an excuse not to do this.

While no one is sure how the crisis will develop, there are already clear learnings about future impact:

- Employees will work differently (and have different expectations). They will be used to different working arrangements, both in terms of physical work and how they are managed and will challenge traditional norms. And with the furlough impact, assumptions about productivity and the need for certain functions has changed. A total reset of organisation structure and focus is under consideration in many businesses.

- Companies know how suppliers and partners dealt with the crisis and are looking at supply chain risk differently. The duress of Covid has exposed structural and performance challenges, and this is being addressed into the future. An example of this is the concentration of raw material supply. One of the large companies we work with quickly discovered an over dependency on one or two suppliers, both in the same geographic area. They are now actively working on a diversified sourcing model going forward.

- Disruptors have emerged and will continue to do so, showing different ways to look at industry and portfolio. In every industry there are new competitors, new routes to market, new potential partners and challengers targeting traditional business models. There has also been internal disruption and re-invention, rapid innovation and multi-tasking. . Examples include changes to technical capacity to produce new products, such as in the case of one of our clients who are now using their machines to make medical equipment We have seen with many clients that long standing norms around roles and capacity have been challenged, and that these changes are being fully integrated in future plans.

- Support services will likely not return to work in full and will position themselves differently in the future. While the physical manufacturing at our plants might be up and running, other departments will take much longer, and might not come back at all. This implies some major changes in how we interact and get the help we need, whether it be technical support, human resources, or procurement.

- The recovery cycle is not clear and caution remains, so there will still be bottlenecks to access critical resources, technology, and skills. At the same time there is a lot of uncertainty, so there will be opportunities to leverage.

1. Clean house: whether it be old equipment, chaotic shop floors, obsolete spares and inventory, or information and data that is no longer relevant, use the restart to clean up and start afresh. With the resource constraints from the pandemic, certain activity might have been de-prioritised – ensure you recover your maintenance schedules, shop floor discipline and housekeeping cycles where they might have suffered during the crisis.

2. Learn from the crisis: Covid challenged our traditional ways of working - and in some cases for the better. Age old paradigms on how to work, share information, or plan operations fell by the wayside, and some employees surprised as they excelled under pressure.

3. Break out of crisis mode: No crisis management process is sustainable in the long term, no matter how exciting it might feel. Where you have crisis teams, war rooms, or special actions related to Covid, be careful not to make this business as usual. Successful firefighting often gives off a feeling of accomplishment, but this is a dangerous habit that creates cost and inefficiency in the long term.

4. Manage financial and performance expectations: accept the impact of the pandemic on efficiency and cost and get over it - your old targets might not be relevant and could be destructive. Ensure you rebalance your recovery and gross margin models for your new reality and drive realistic targets that incentivise your teams in the right way.

5. Plan to be agile: look for improvements and investments that increase agility. Focus on skills and culture that can accept and respond to change. Work with your suppliers and distributors to build a receptive end to end response. An example at one of our clients has been a complete change in their investment strategy for equipment, from using highly efficient long run machines, to machines that are more flexible, and can run different pack configurations.

6. Ensure you are innovation ready: can your teams trial, test, and procure in a way that will support the changing needs of the business in a positive way? Innovation is also about having the right mindset to positively impact business efficiency and output.

7. Lock in your critical requirements: get to the front of the queue for key investments, innovation support, and material supplies. Secure the critical skills you need now and in the future. Make sure you are ahead of the game once things start turning and everybody is fighting for the same limited requirements.

8. Relook at your geography: over the last few decades many organisations have looked for cost-efficiency through international and single-sourcing, and rapidly expanded into new markets using assumptions about distribution effectiveness. Many were caught short with their long supply and marketing chains. Whether it be local sourcing, route to market, or risk management, a review of your geographic risk profile might be in order.

9. Train your decision muscle: you will need to be able to make quick, brave decisions in a rapid recovery cycle. Build trust in your market sensing - there will not be time for major revisions or investigations if a quick decision is needed. And get your RFPs and RFIs ready for potential change - don't start when you need it, especially if these processes are traditionally onerous in your business.

10. Choose your process support investments carefully: aim for process and business improvements that have the right return on investment, linked to your future growth plans. Select digitisation projects that are fit for purpose and scalable - not overly burdensome with lots of complexity and design rigidity. Where your team is required, ensure their time is used wisely and that learnings are sustainable.

Everything we have seen shows us that for the businesses that can adapt and be ready, recovery will quickly lead to growth and accelerated performance, but also that winning the Covid battle will by no means guarantee continued future success.

The world is not going back to where it was before the pandemic. Businesses need to plan for a new normal, and as a manufacturing leader, your role will be critical in ensuring this.