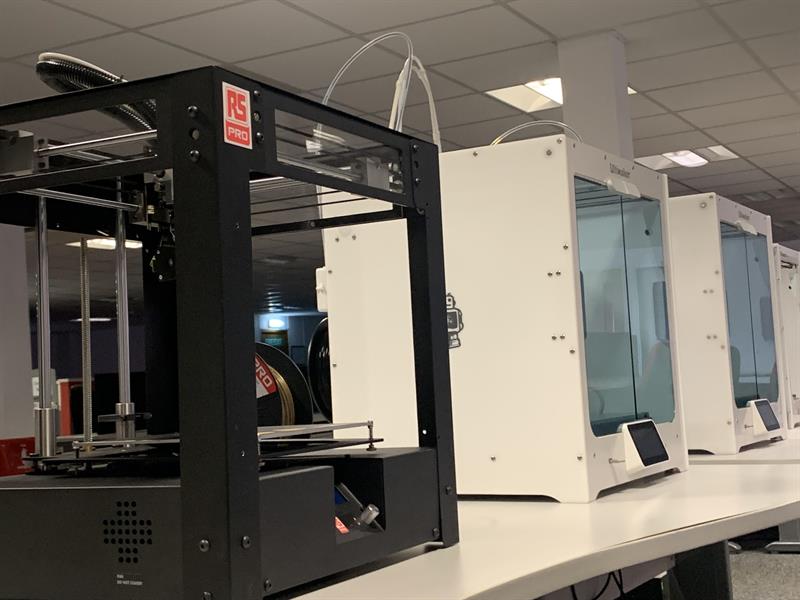

1230: RS Components rallies 3D printing community

RS Components has embarked on a partnership with the National 3D Printing Society (N3DPS) to enable frontline health workers to quickly access vital personal protection equipment (PPE) as they tirelessly continue their efforts to combat the COVID-19 virus. To directly support this urgent action, RS has teamed up with its RS PRO supplier to donate 400kg of PLA filament to N3DPS from end-of-reel-supplies. This quantity of filament will be enough to produce up to 20,000 visor frames and is available to users who join the N3DPS campaign.

Over the past two weeks, RS has reached out through its DesignSpark engineering platform to the 930,000-strong DesignSpark community, urging members with access to a 3D printer to join an urgent campaign (https://www.rs-online.com/designspark/do-you-have-a-3d-printer-you-can-help-to-fight-covid-19) to produce NHS-accepted protective visors, to help shield medical and care professionals at high risk of contracting the coronavirus.

RS has also been developing a 3D printing farm in Corby, Northamptonshire, which aims to produce over 1,000 visors per week for this initiative. N3DPS has kindly agreed to loan a number of its machines to support this. The printing farm is due to commence production during week commencing 20 April, boosting the number of 3D printers making visor frames for use by health professionals across the country.

---------------------------------------------------------------------------------------

1215: 3T & EOS 3D print 100,000 shields for healthcare workers

3T-am, a leading production additive manufacturing (AM) company, is utilising EOS’ global partner ecosystem to 3D print face shield headbands for frontline health workers in the UK.

3T is now producing 20,000 headbands per week, and will exceed 100,000 within the next few weeks. The face shields are being used by frontline workers, across the NHS and UK healthcare system, fighting the COVID-19 pandemic.

During times of such uncertainty, manufacturers are under increasing pressure to deliver essential products and services. It has arguably never been more important for a flexible and efficient supply chain. 3D printing allows for tens of thousands of high-quality parts to be produced in a matter of weeks, when people need them most.

3T is working directly with NHS trusts across the UK, as well as various medical distribution companies to supply face shields to UK health workers. 3T has also provided the CAD for free, available to download from 3T’s website.

---------------------------------------------------------------------------------------

1145: Make UK expands online learning service

Make UK has expanded its online training and learning services for companies to ensure that manufacturers are able to pivot their business to operating through the Covid 19 crisis and, in particular, to safeguard the future of their workforces now and in the future.

As well as operating a Coronavirus hub which gives companies access to the official Government advice and support schemes, since the start of the crisis Make UK has transferred all its HR & Legal, Health & Safety and Apprentice Training online, whilst continuing to introduce new services to help companies such as remote cyber security protection for individuals working from home.As a result of its focus on helping manufacturers with business continuity Make UK is now training a record number of almost 2,000 Apprentices online. The interactive training is being delivered remotely with a smart assessor being used to support online assessment while mentoring and coaching is also available to students.

---------------------------------------------------------------------------------------

1100: Textiles firm produces 3.5 million metres of fabric for healthcare services

North West based workwear fabric manufacturer Carrington Textiles, has increased capacity at its main processing facility in the UK to supply the domestic and international healthcare sector with the fabrics urgently needed for PPE in the fight against the COVID-19 pandemic.

Working around the clock with some of the biggest garment providers to the NHS and the healthcare sector in France, Germany, Eastern Europe and Scandinavia, Carrington Textiles has supplied over 3.5 million metres of fabric in the last 5 weeks, a demand two times greater than usual, with 2.5 million metres alone serving the NHS, care homes, pharmacies and other front line healthcare professionals in the UK.

The latter figure will be enough to provide more than one million sets of uniforms, including scrub suits or tunics and trousers, to key workers who need them the most. Another 300,000 metres of Carrington Textiles’ healthcare specialised fabrics will clothe frontline staff at Nightingale Hospitals around the country.

Additionally, as manufacturers from the fashion industry re-purpose their production for scrub suits, Carrington Textiles has also been there to support with much needed supplies of fabric.

---------------------------------------------------------------------------------------

0930: Automotive manufacturer offers factory for Covid-19 equipment use

A company that makes parts for the automotive industry has offered its premises, 45 and equipment for the production of PPE or any other essential products in the fight against Covid-19.

Interflex 2000 in Nottinghamshire, which normally makes sealing solutions for car door seals, boot lids and interior trim, has temporarily furloughed its production staff as the company’s customers, which are mainly UK vehicle manufacturers, have also ceased production.

Managing Director Jim Griffin (pictured) explains why he has come forward to offer Interflex’s facilities. “In the current situation, we are unable to manufacture for customers, but it seems a waste to have equipment and staff available at a time when the country urgently needs products that we could help supply. If nothing else, we have a large facility so can utilise space to help reconfigure packages or offer storage as required.”