When thinking about the word ‘innovation’, it doesn’t usually conjure images of factory floors. Instead, most think of technology innovation or a marketing team, in a room filled with bean bags and sticky notes haphazardly stuck to the wall.

For many business leaders, the machinery needed for an innovation is a secondary consideration. The preference is often given to spending money on new production facilities to produce the latest innovation, instead of creating new products they already have the capability to make. The majority of business leaders seem to agree too, with 86% believing that production capabilities are not often considered when developing new products and innovations, according to research we undertook earlier this year.

The factory floor is a sleeping giant for innovation and attitudes need to change.

So, why should innovation move down to manufacturing?

Fuelled to innovate within FMCG (it’s not called fast-moving consumer goods for nothing), business leaders are blinded by a need to find ‘the next big thing’, from the next Uber to the next Dyson. However, new innovations rarely succeed, with three in four FMCG launches failing within a year, according to Nielsen. To really lift the lid on the landscape, between 2011 and 2014 there were over 12,000 new launches across Europe, and of those over two thirds never achieved 10,000 unit sales, meaning the majority failed to retain a retail listing beyond their first year.

In the face of such risk, you have to wonder why senior business leaders are still pursuing the big break-through and investing so much in blue sky thinking and new machinery, while assets already at their disposal for innovation purposes are left to gather dust.

Underutilisation of a factory will hit profits of a company, because costs are proportionally higher, not to mention the opportunity cost represented by the capacity not being used. In fact, according to our research, factory utilisation rates typically hover around 80%, leaving plenty of room for improvement.

Focusing on small innovative changes, considering how the product would be made, and how to best use the machinery you already have, can lead to lower risk, a higher capex, and greater odds of success. And in turn, increase utilisation of your factory.

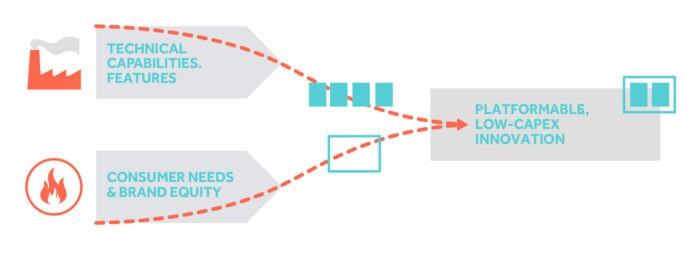

At Happen, we believe in creating new ideas with what your factory can already make, a methodology we call Asset Out. The methodology enables a person to leverage their business’s technical capabilities and manufacturing assets for immediate competitive advantage. We work with companies to move the manufacturing capabilities to the start of the process, shifting attention away from the ideas which don’t consider the reality of production. Nevertheless, it’s still a very creative process, stretching what the factory could do beyond what it currently does, resulting in surprising new product features within the guardrails of operational reality.

This thinking allows a factory’s efficiency to be kept while at the same time new products can be developed. For example, Arla Food’s Best of Both milk was created out of this method, additionally the method was used by Mondelez’s global chocolate and biscuits teams to identify over 600 new product features that can be used in various combinations to launch new products, all of which can be made without the need to buy new machinery.

The Innovation mindset

Before innovation is even mentioned in relation to manufacturing and the production line, you need to change mind-sets across an organisation.

Culturally, too many organisations perceive their manufacturing assets as ‘locked’. Machines that have been honed to perfection, like a Formula 1 car. As a consequence, they never consider their factories as the well-stocked kitchens they really are, wide open for opportunity for creating new types of products at low investment. Additionally, as stated above, innovation is thought to be the realm of marketing departments, who often have little understanding of the manufacturing process. This has meant that their R&D/Ops/Tech counterparts are working with a ‘can’t do’ mind-set. No bad intent, just different KPIs. Lacking that positive, pragmatic mind-set, most businesses never innovate to their full potential because of the prohibitively expensive investment into new assets, or end up compromising on innovation quality in order to get it through their systems.

To change this mind-set, consider the traditional economic terms of supply and demand. Every innovation challenge has a supply and demand side; what innovations do customers want versus what innovations can organisations provide. Too often the focus is on the demand side, with market research (which deals primarily in demand) tipping the innovation focus on what the customer wants. A good innovation is perceived as one that primarily meets customers’ needs, regardless of whether or not a company can make it.

Shifting an organisation’s mind-set away from the demand side to the supply side allows the definition of successful innovation to open up. So, with Asset Out innovation a company can provide a new way of thinking of products, a cheaper way of creating new products, both leading to successful innovation.

Future-proofing your business

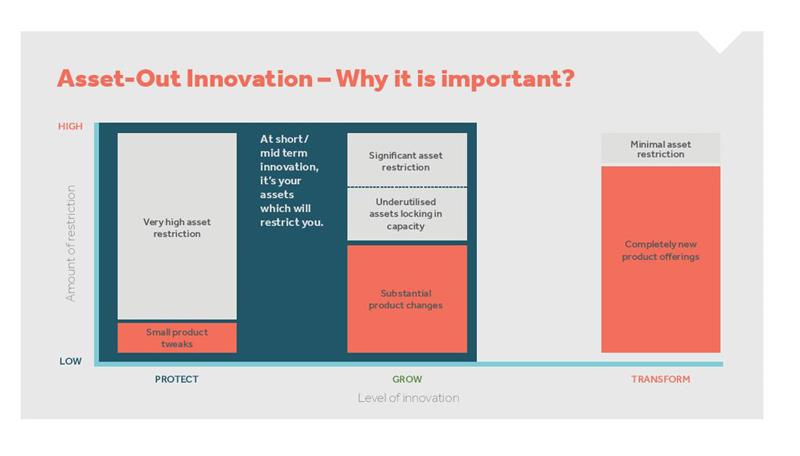

The Asset Out methodology works for protective and growth innovation: these kinds of innovations don’t require a lot of investment to be truly transformative. As the below infographic demonstrates; it’s is not designed to create a category-disrupting innovation, instead it provides a process for an organisation to protect its market share by staying fresh and relevant to consumers or to grow market share by convincing existing consumers to buy more, and attracting new ones.

More often than not, the focus of innovation is on creating transformative change, which requires more investment, and carries greater risk. With little innovations, you are more nimble and small tweaks can be made which can create a big difference.

More often than not, the focus of innovation is on creating transformative change, which requires more investment, and carries greater risk. With little innovations, you are more nimble and small tweaks can be made which can create a big difference.

A factory is not simply a production line honed to create one product, it is also a kitchen, with the ability to inspire and create new ideas with its variety of tools. By changing the mind-set and approach towards innovation, manufacturers can become a true part of the innovation process, enabling large organisations to act like their nimble smaller competitors.

To find out more about production taking ownership of innovation check out our new Asset Out whitepaper.