Recent studies by the Carbon Trust have revealed that despite pandemic disruption and extremely challenging market conditions, over 70% of companies are continuing to prioritise sustainability and environmental management issues. Wherever energy is consumed we must use it smarter. Since 10% of global electricity consumption goes to generating compressed air, a place where air compressor manufacturers can make a real difference is in developing solutions that make compressing air more energy efficient and that support manufacturers in their journey towards carbon-neutral production.

Reasons for going green

It’s all about energy efficiency and carbon reduction. Energy costs make up 80% of a compressor’s total cost of ownership. So, investing in environment-friendly compressors, and optimising existing air systems that use significantly less energy, can sharply reduce both the production cost of compressed air and a company’s carbon footprint.

But how much energy can be saved by going green? This is a particularly important question for smaller companies, which may be concerned about the higher initial purchase price of an energy-efficient compressor. To some, it might seem that the “safe” option would be to take the risk of keeping on using their old compressor even though it attracts a disproportionately high electricity bill.

The fact remains that not switching to environment-friendly technology is much riskier. It invites a degree of uncertainty about equipment reliability and ability to maintain production processes.

Green air compressors provide stability. They guarantee that a company will lower the production cost of compressed air, protected from fluctuating energy prices. A green compressor offers greater reliability, longer maintenance intervals and ensures compliance with all current and upcoming emissions standards.

Assessing compressor needs

While environment-friendly compressors are all about efficiency, picking the right model still matters. That means buyers have to be aware of their compressed air needs: How much airflow and pressure do they need and for which applications? Will the compressor run constantly or intermittently? How important is air quality? Does the air demand fluctuate or remain steady?

Carrying out a non-intrusive energy audit to measure the efficiency of an existing compressed air installation, involving the use of data logger, is the best way to discover possible energy savings from a compressed air system. Combined with plans for specific future requirements, this data allows plant operators to understand and improve their system’s energy efficiency.

It also answers many of the questions that help to determine the ideal size and type of compressor − whether a model with variable speed drive is better for fluctuating air demand, whether a piston compressor is sufficient for intermittent use and limited air demand, or is a rotary screw compressor best suited for the application need.

Choosing the most energy-efficient solution

If an application requires a constant speed at all times, then a fixed-speed compressor will often get the job done. Once it is switched it on, it gives full power. Most industrial applications, however, have a fluctuating air demand. In that case, a variable speed drive (VSD) compressor is the better choice because it matches output to user demand and will realise considerable energy savings in the long run. A VSD or VSD+ compressor will reliably deliver top quality air while lowering energy consumption by an average of 50%.

When a business decides to go green and switch to an environment-friendly air compressor, then it has already made the most important and beneficial choice. However, in making that choice there is another major consideration, the Total Cost of Ownership (TCO). Compressors are a prime example of how pronounced the difference can be between initial investment and the TCO.

How going green makes sense financially

The total cost of ownership of a compressor consists of the cost of buying, owning, and operating it during its lifetime. As a rule, because of manufacturers’ technology developments embodied in advanced, environment-friendly compressors, these units may carry a higher price tag, but they also offer much lower operating costs, which provide payback in the long run.

In fact, the initial investment constitutes only a small fraction of the TCO. Energy costs make up the bulk of it and will likely become an even more important issue in the near future if energy prices continue to rise despite evident progress in, and nationwide dependence on, sustainable alternative energy sources.

It is true that not all businesses are ready to embrace the need for “going green.” Sceptical managements may still believe that green investments are prohibitively expensive. Nothing could be further from reality. There is a wealth of evidence in the form of compressor-user case histories documenting annual running costs reductions of well over 30% and payback periods of less than two years.

Going green is not just about buying a new compressor. Aside from the return on investment, taking the right level of care of an established installation can also make a substantial contribution to the cost benefits of going green.

Apart from the basic function of providing an air supply to production processes, green compressor technology can contribute to comfortable workplace environments while at the same time achieving significant energy savings. That is its heat recovery role.

Compression heat is the key to unlock the green compressor house of the future

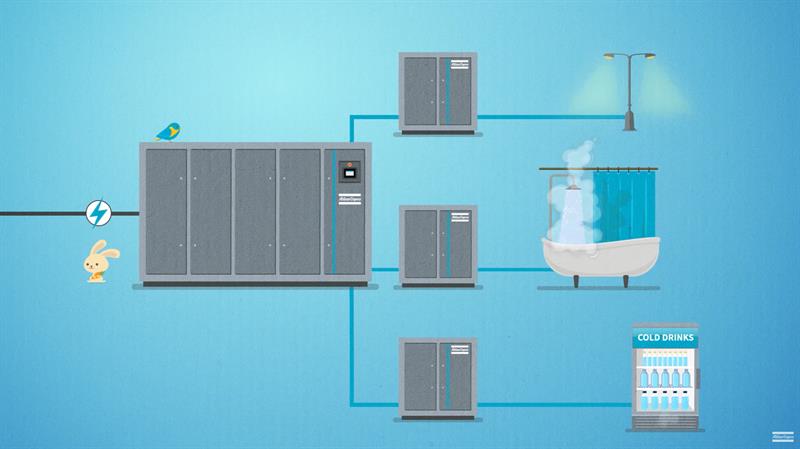

Energy has a remarkable feature – it never diminishes but is transformed into other types of energy. Compressors generate heat. Most businesses allow this heat to dissipate as quickly as possible to keep the ambient temperature down. But there is a better way - heat recovery.

Instead of letting it go to waste, purchasing a compressor with integrated energy recovery or installing a heat recovery system between the compressor and the cooling- and heating circuits will recover and re-use 70-94% of the energy required to run a compressor. The hot water, heated up to 90 degrees C and recovered from the compressed air system, can be used for sanitary purposes and space heating but is particularly suitable for process-heating applications.

Recovering heat from compressed air reduces the need for purchasing energy. It is this reduction that results in lower CO2 emissions and operating costs. Due to the high cost of energy, these savings can be significant in terms of helping companies to meet their carbon reduction targets and improve manufacturing plant profitability.

Staying green: The importance of maintenance and control

Optimising an existing compressed air network typically offers businesses more than one option to reduce their carbon footprint and the cost of compressed air. A compressed air system requires attention and care. Neglecting it invariably leads to inefficiencies that can prove to be quite costly.

That is why a compressed air system should be regularly maintained, continually monitored, and carefully controlled. While the support of the supplier’s scheduled maintenance plans should be mandatory, to ensure the system’s overall health and performance, the compressor user’s day to day operational vigilance is equally vital.

A simple example is that of the working air pressure. A higher pressure means increased energy use, which means higher production costs. An increase of just one extra bar of pressure results in an average of 7% more power required. That quickly adds up to a substantial increase.

Operators should always be aware of how much pressure they actually require and where their system may lose pressure. As a rule of thumb, the compressed air network should be designed so that the loss of pressure between the compressor and the most distant piece of equipment that consumes the air should be no greater than 0.1 bar.

The best way to manage a compressed air system is to install a state-of-the-art master control system that monitors its efficiency, availability, and reliability. Not only can it detect problems, but it can automatically reduce the working pressure – and energy costs - when the air demand is low. The controller can also be paired with smart connectivity technology to monitor and optimise a compressed air system from a remote location.

While pressure and flow can be readily measured and controlled, it is equally important to ensure the quality of air supplied from a green system meets the required standard.

Guaranteed compressed air quality in green production

More and more companies are realising that “going green” is not just the right thing to do but also makes sense financially. However, this often raises the question of whether switching to ecological equipment and production processes can ensure quality.

For businesses where it is critical to meet extremely high standards in their process air requirements, green technology should only be employed if it guarantees that final products are not compromised. It can be argued that for applications such as clean rooms in pharmaceutical production, food and beverage production, or electronics manufacturing, maintaining stringent quality standards is much more important than using the most environment-friendly equipment.

That is why the compressed air industry’s offerings are subject to strict compliance with quality standards such as ISO 8573-1 and ISO 22000.

In order to protect sensitive processes, premium air treatment equipment, such as oil-free compressors that are ISO 8573-1 Class 0 certified, produce high air quality air that is free of oil vapours, aerosols, and other contaminants. Supplier companies that are ISO 22000-certified have demonstrated a commitment to provide clean and safe food production systems.

Other good reasons to go green

Tighter government emission standards. Governments not only try to meet their emissions targets through incentives but also through more stringent emission standards and other environmental regulations. Only investments in cutting-edge, green technology can ensure that compressor equipment will comply with new environmental rules for some time to come. Older compressors may soon no longer qualify under existing rules.

Going green is the right thing to do. The overwhelming majority of scientists, and study after study, tell us that the planet is warming at a rate that will radically change how we live on it. In fact, natural disasters like droughts, wildfires, floods, and storms are already gaining in strength. Even more reason for compressor manufacturers to innovate solutions that help customers become carbon free and for production companies to embrace the material benefits of such green technology and together fight against climate change.